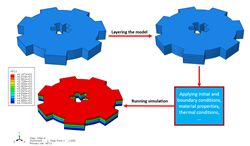

Basics of 3D Printing Simulation: Answering Key Questions

This article provides a comprehensive overview of additive manufacturing simulation, which involves virtually testing and optimizing the 3D printing process.

Additive Manufacture: In-house 3D Printing versus Outsourced 3D Printing Service

In this 3-part series of articles, we will embark on a comprehensive exploration of 3D printing / additive manufacturing (AM), where our main focus is empowering you to make informed decisions about how to engage with the technology across an ever-evolving landscape.

Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

There aren't a lot of technologies that can propel towering wind turbines to new heights of time and cost efficiencies, but large-format additive manufacturing rose to the challenge and delivered with its eclectic range of applications.

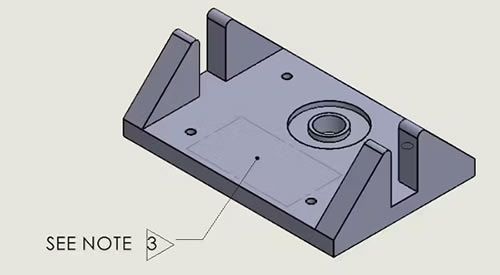

How to Create A Good Technical Drawing

Make sure your drawing undergoes all quality assurance and approval procedures. A drawing that is easy to follow and clearly defines your requirements is one of the first steps to a successfully manufactured part.

Manufacturing Impact: Rising Consumption of Entertainment Drives Demand For 3D Animated Content

The augmented demand for the technology from several industrial verticals due to the increasing use of simulation in the design of industrial tools by OEMs has facilitated the penetration of 3D animation solutions worldwide

Why Binder Jetting?

Besides being fast and capable of manufacturing complex shapes, binder jetting systems are also incredibly accurate.

Dynamic Micro-CT: Moving beyond 3D into 4D

In general, dynamic micro-CT is ideal for obtaining much more complete 3D information throughout a process and provides researchers with a lab-based capacity to collect data during testing without discrete interruptions"•true in situ testing.

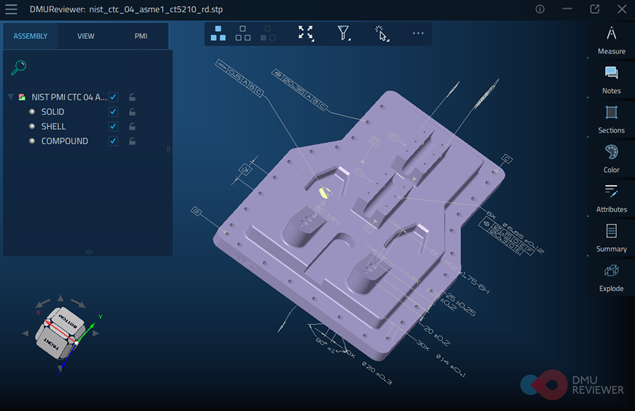

Model-based enterprise as a trigger to Digital Transformation

When it comes to industrial and manufacturing design and engineering, here we speak about low paced movement from 2D drawings to 3D models which are definitely more informative, easy-to-use and more adaptable to changes.

3D modelling technique for fast-track face shield production

Using stacked model data, the technique can dramatically increase 3D printing output, assisting in producing face shields for healthcare workers fighting COVID-19.

CRP Technology and Windform® Materials for 3D Printing are Driving AM Revolution

Some of the most advanced industry - as Automotive - are experiencing a renaissance not seen before, which is driving engineers to find new, innovative, cost-effective solutions using professional 3D Printing, mainly.

MODEX Q&A - Emulate3D

This year at MODEX we'll be highlighting CAD Is The Model technology, which enables system designers to mark up their solutions in SOLIDWORKS and Autodesk Inventor and create articulated and dynamic systems for emulation testing.

Booth #7869

Case Study: Phase Four Launches Scalable Electric Propulsion (EP) System with Xometry

This innovative California-based aerospace company is revolutionizing space exploration with Maxwell, its mass-producible EP system. Xometry is the manufacturing platform that's bringing its exoskeleton from its 12-page drawing to life.

GE Additive & Kaspar Schulz Q&A - Additive Manufacturing: there's always something brewing!

This year we wanted to go a layer deeper and explore the potential that additive technology could have on the brewing and beverage industry.

Rockwell Automation Acquires Emulate3D, a Leading Software Developer for Simulating and Emulating Industrial Automation Systems

Software portfolio integrates automation software with 3-D CAD model, enabling customers to test machine and system designs virtually

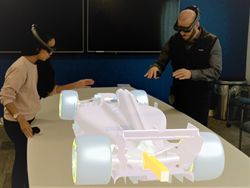

Onshape Teams Up with Magic Leap for New Spatial Computing CAD App

New product design app to offer live collaborative 3D CAD editing, not just viewing

Records 1 to 15 of 39

Featured Product

FLIR Si1-LD - Industrial Acoustic Imaging Camera for Compressed Air Leak Detection

The FLIR Si1-LD is an easy-to-use acoustic imaging camera for locating and quantifying pressurized leaks in compressed air systems. This lightweight, one-handed camera is designed to help maintenance, manufacturing, and engineering professionals identify air leaks faster than with traditional methods. Built with a carefully constructed array of MEMS microphones for high sensitivity, the Si1-LD produces a precise acoustic image that visually displays ultrasonic information, even in loud, industrial environments. The acoustic image is overlaid in real time on a digital image, allowing you to accurately pinpoint the source of the sound, with onboard analytics which quantify the losses being incurred. The Si1-LD features a plugin that enables you to import acoustic images to FLIR Thermal Studio suite for offline editing, analysis, and advanced report creation. Field analysis and reporting can also be done using the FLIR Acoustic Camera Viewer cloud service. Transferring of images can be managed via memory stick or USB data cable. Through a regular maintenance routine, the FLIR Si1-LD can help facilities reduce their environmental impact and save money on utility bills.

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.