Powering Additive Manufacturing with an Environmental and Social Impact Commitment

Structured ESG and strategic, measurable sustainability programs are unlocking the deep value behind "doing well (profitability) by doing good (sustainability)."

Rethinking material usage - How 3D printing enables dematerialization

3D printing makes it possible to introduce different materials into production that offer a lower embodied energy. In many applications, polymer or composite materials can offer the same strength and durability as metals.

It's time for change - Technology essential to tackle climate change

To pursue a sustainable future, manufacturers need to find options to increase energy efficiency. Industrial robotics is an ideal way to help improve sustainability and minimize the environmental impact of manufacturing activities.

How to Conserve Water in Your Manufacturing Process

There are many specific actions you can take to conserve water during your manufacturing processes, and the first step is finding and fixing unwanted leaks in your equipment and machines.

Using Sustainable Product Configuration to Enable Customer Choice

Traditionally, when we think about the cost of a product, we're thinking mainly in financial terms. But this isn't the only form of cost. Increasingly, a new measure that's taking on more importance for buyers - and regulators - is the carbon footprint cost.

Keys to Biocompatible and Hypoallergenic Manufacturing

The materials approved for use in biomedical implants are limited, but as new alloys and polymers emerge, the chances are high that many of them will prove to be biocompatible as well. These will help to shape the future of biomedical manufacturing as a whole.

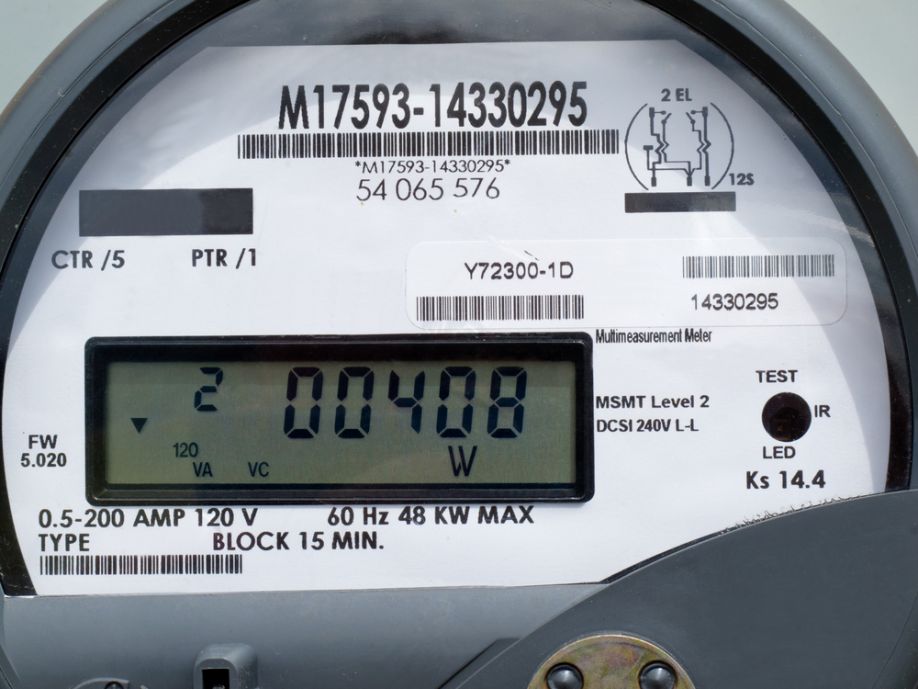

Creating Energy Resilience in Your Manufacturing Facility

Achieving energy resilience at a manufacturing facility or elsewhere is a two-part process. First, it requires ensuring you have a reliable power supply. Next, an energy-resilient company must have thorough plans for how to respond if a power failure occurs.

Promoting Sustainability in Plastic Manufacturing

In light of that negative reputation, the plastic manufacturing industry needs to initiate changes to make the entire sector - as well as the product itself - more sustainable. What can we do to promote sustainability in plastic manufacturing?

IDS focuses on sustainability in shipping

IDS is convinced that the changeover to sustainable action is the only right way forward and tries to develop resource-saving solutions together with business partners. After all, relatively "small" changes can make a big difference - for the environment and for the company.

A Sustainability Process That Drives Business Value

Iota has developed a framework called the Sustainability Process Blueprint that allows businesses to easily monitor, measure, and curate data pertaining to their sustainability performance.

Records 31 to 40 of 40

Featured Product

The Wire Association International (WAI), Inc.

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry. WAI hosts trade expositions, technical conferences, and educational programs.

Manufacturing and Automation - Featured Company

EXAIR

EXAIR intelligent compressed air® products solve problems in industrial plants while reducing compressed air consumption and increasing safety for personnel. We have the largest variety of sizes, materials and performance characteristics in order to provide the best solution for your processes and problems.

Our products are commonly used to conserve air, cool processes or parts, convey material, clean surfaces or coat surfaces. EXAIR's 15 extensive product lines include air knives, air wipes, air nozzles and jets, atomizing nozzles, static eliminators, cold gun air coolant systems, air amplifiers, safety air guns, air operated conveyors, industrial housekeeping products, vortex tubes and spot cooling products, cabinet cooler systems, vacuum generators, compressed air optimization products, and associated accessories.

Products meet OSHA standards and are CE and RoHS compliant. Five-year warranty on compressed air products and one-year warranty on accessories and electrically powered products.