How Machine Vision is Enhancing Automation Safety and Efficiency

Technologies to extract high-level meaning from images are increasingly common. Within the research community, such technologies are often considered different from machine vision. However, all are different ways of achieving machine vision and in many cases overlap.

IDS: See. Align. Place.

For both machines, the manufacturer relies on industrial cameras from the USB 3 uEye CP series from IDS Imaging Development Systems to ensure maximum accuracy, speed and process control. These systems are already in high-volume use across the Asian electronics market.

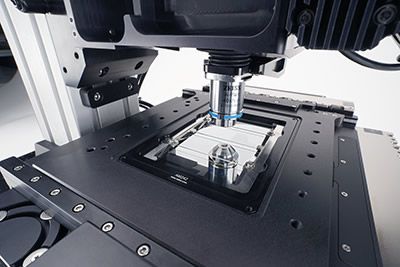

Case Study: Affordable Dual-View Microscope System

Zaber's Nucleus® microscopy modules share a common control protocol mounting features, and optical and electrical interfaces, enabling them to be combined in ways that are simply not possible with other microscopes.

Beyond the Camera: Network Choices that Impact Machine Vision Systems

As automation accelerates, understanding the network that connects hardware with software will help ensure that machine vision systems operate at their full potential.

High-speed image analysis of the smallest particles in real time

Particles can vary widely in form and origin - be it powder, liquid, tablet, sand, microplastic or pigment. In order to analyze this diversity, laboratories must master a balancing act between precision, efficiency and practical requirements.

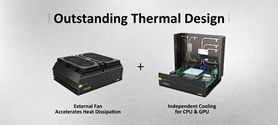

Computers for Edge AI, Machine Vision, and Industrial Automation Applications

The market demand for solutions that combine high performance, compact size, and high reliability is rapidly increasing, especially in harsh environments such as smart manufacturing.

The Important Role of Thermal Imaging for Condition Monitoring

Manufacturing and production processes consistently face challenges in ensuring the longevity and efficient functioning of their equipment, especially as they age.

Three eras of machine learning - A new paradigm

Simple rule-based algorithms have been used in the visual inspection market for many years, but as their limits have become more apparent, the need for more sophisticated software has grown.

Revolutionizing Machining Operations with Artificial Intelligence

The synergy between AI and CNC machining is set to reshape the future of manufacturing. Embracing these innovations will empower industries to achieve new levels of excellence, driving growth and success in an increasingly complex market.

Pallet by pallet - Intelligent robotic vision system destacks up to 800 objects per hour

One of the locations where RODE adds value is for DHL eCommerce in Rotterdam. In this machine, two Ensenso 3D cameras from IDS Imaging Development Systems GmbH are implemented to provide the required image data.

The Core of Optimizing Robotic Performance: Sensors in Warehousing

Without any external input to guide its actions or decisions, a robot would behave like a machine, performing tasks without adaptation or autonomy. Serving as the critical link between the robot and its environment, sensors enable the robot to perceive and interpret.

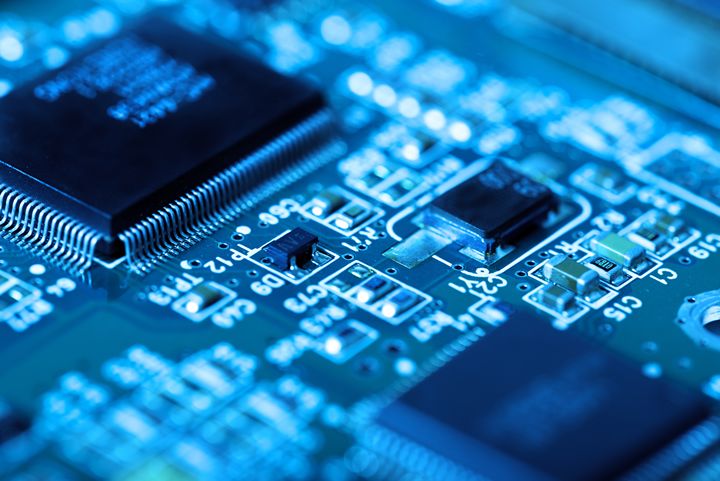

Inspecting Miniaturization: How 2D Laser Profilers Handle Tiny Electronic Components

The miniature size of modern electronic components makes placement, mounting, soldering, and testing of said components rather difficult. Given their size and the overall component density on the PCB, visual inspection is nearly impossible.

Why e-con systems' latest 5MP Global Shutter camera - e-CAM56_CUOAGX is ideal for factory automation

Embedded vision has transformed factory automation - thanks to advances in sensor technology, processing power, and AI. Discover the key features of e-CAM56_CUOAGX, e-con Systems' latest camera and see why it's perfect for factory automation.

How Ethernet Cameras Are Making a Comeback with New, Powerful Features

In this blog, you'll get expert insights about the role of Ethernet cameras in embedded vision, their challenges, and the exciting features that continue to make PoE technology extremely valuable.

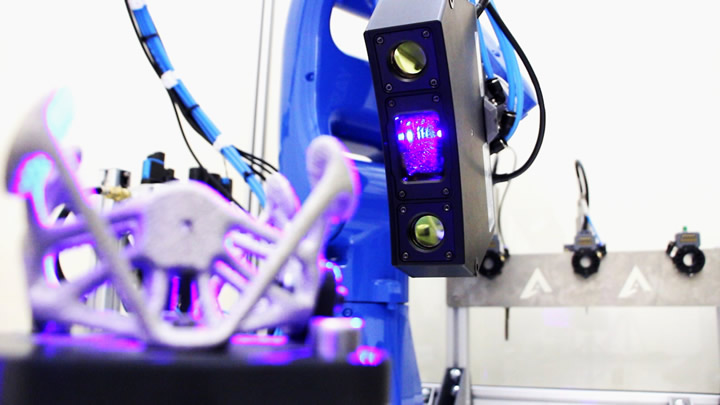

The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

In 2024, post processing metal parts is still a bottleneck in the AM process chain because it is still very often a manual, labor-intensive, messy (filthy, actually) and sometimes risky task.

Records 1 to 15 of 70

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

Manufacturing and Automation - Featured Company

The Wire Association International, Inc. (WAI)

The Wire Association International (WAI), Inc., founded in 1930, is a worldwide technical society for wire and cable industry professionals. Based in Madison, Connecticut, USA, WAI collects and shares technical, manufacturing, and general business information to the ferrous, nonferrous, electrical, fiber optic, and fastener segments of the wire and cable industry.

WAI hosts trade expositions, technical conferences, and educational programs.