The Evolution of Additive Manufacturing: How Automation Redefines Post-Processing Standards

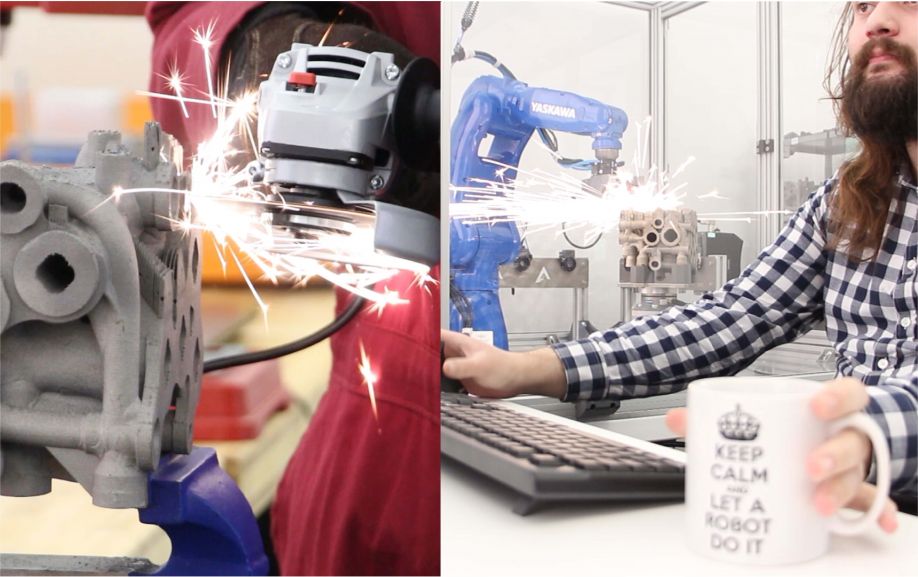

In 2024, post processing metal parts is still a bottleneck in the AM process chain because it is still very often a manual, labor-intensive, messy (filthy, actually) and sometimes risky task.

THE RISE OF AUTOMATION IN METAL AM POST-PROCESSING - TRANSFORMING THE INDUSTRY WITH PRECISION AND EFFICIENCY

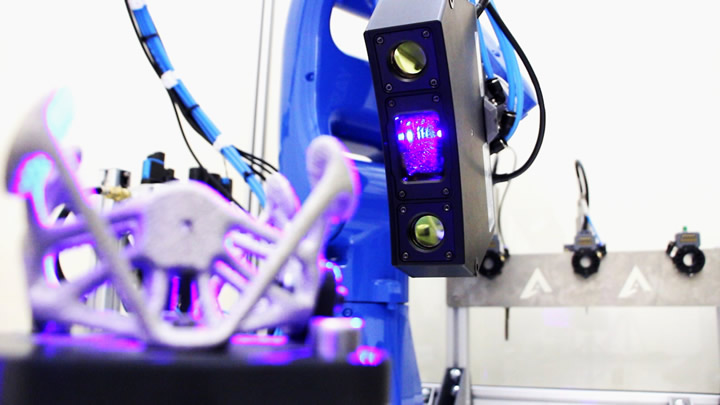

We delve into how automation in metal AM post processing is setting a new industry standard, and how companies like Rivelin Robotics are leading this change with their Netshape® Robots to unlock new productivity and efficiency gains.

REFLECTING THE FINISH: THE CRUCIAL ROLE OF POST-PROCESING IN AM

With a holistic approach that combines advanced printing technology with equally advanced finishing techniques, AM is redefining manufacturing, offering unprecedented agility, efficiency, and quality to industries around the world.

AM Post-processing: Benchmarking Alternative Technologies

With a variety of post-processing technologies available, it is essential to understand their capabilities and limitations. In this article, we will benchmark different post-processing technologies and explain why mass finishing technologies are the best fit and the most efficient solution.

Weerg achieves cycle time reductions of over 50% with post processing technologies from AM Solutions

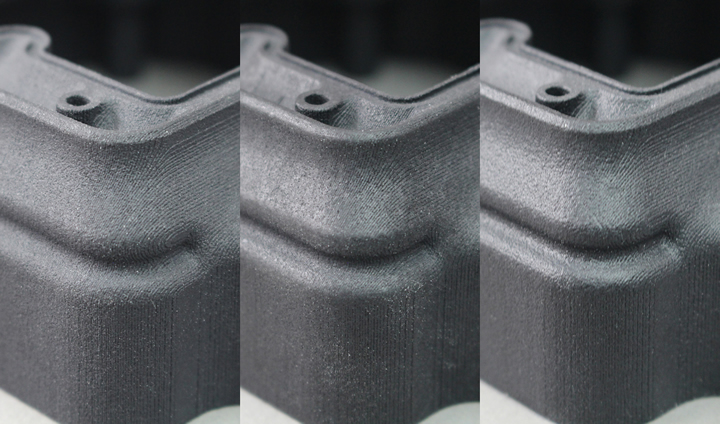

While order processing and manufacturing of the 3D components was managed digitally early-on, numerous post processing operations still had to be done manually, which required a lot of time and personnel and produced inconsistent results.

The Role of Wet Blasting in the Post-processing of AM Parts

Many companies are working on and researching new bespoke AM post-processes, sometimes with impressive results, but usually restricted in usefulness to particular materials or geometries, and almost all being highly priced and over-engineered.

AUTOMATED POST PROCESSING SOLUTIONS: PROS & CONS

There are a number of reasons to apply optional post processing to parts, including but not limited to advantages gained in terms of aesthetics, part performance,e and improved material properties.

Post Processing in 3d Printing - the Key to Viable Production Outcomes

When we specifically consider the use of 3D printing for production applications, the industrial 3D printing machines themselves are actually just one part of an extensive ecosystem of technologies that enable the production of parts, both pre- and post-build.

Post-processing - Enabling Additive Manufacturing

In this article, Joseph Crabtree, CEO at Additive Manufacturing Technologies Ltd considers the importance of post-processing in the entire production process chain and highlights an emerging solution.

Records 1 to 9 of 9

Featured Product

Cold air to -50°F (-46°C) from your compressed air supply - with no moving parts!

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts.

Vortex tubes can produce:

"¢ Temperatures from -50° to +260°F (-46° to +127°C)

"¢ Flow rates from 1 to 150 SCFM (28 to 4248 SLPM)

"¢ Refrigeration up to 10,200 Btu/hr. (2571 Kcal/hr.)

Temperatures, flows and refrigeration are adjustable over a wide range using the control valve on the hot end exhaust.

EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation. https://exair.co/184_530

Manufacturing and Automation - Featured Company

Parvalux Electric Motors Ltd

Parvalux is a leading global manufacturer of geared motor solutions with over 70 years' experience in creating the perfect combination of motor and gearbox to match the customer's application. Whilst we offer thousands of standard options we can easily customize any motor or gearbox to meet your exact requirements at no or minimal extra cost. Our design team can work closely with your own to optimize your solution for your application helping you to secure a genuine competitive advantage in your market. Our products are found in hundreds of applications but we are particularly strong in healthcare, leisure, mobility, transport, and a diverse range of industrial applications.

.jpg)