Transportation & Logistics Company Cuts Costs and Improves Asset Tracking with HiveMQ

As the shipping and logistics company scaled and especially during their peak season between Black Friday and Christmas, the number of devices, connections, and topics being created overwhelmed the broker, causing a lot of headaches.

Four TCP-based Communication Protocols That Are Key to IIoT-Part 4: REST API

Representation State Transfer (REST) summarizes architectural frameworks that simplify and harmonize communication between devices in a network. It was developed in 2000 by Roy Fielding as part of his Ph.D. thesis.

Four TCP-based Communication Protocols That Are Key to IIoT-Part 3: AMQP

The Advanced Message Queuing Protocol (AMQP) is an interoperable asynchronous publish/subscribe communication protocol. It was originally developed in 2003 by the JPMorgan Chase Bank.

Four TCP-based Communication Protocols That Are Key to IIoT-Part 2: OPC UA

OPC Unified Architecture (OPC UA) is a platform-independent, service-based architecture. A successor to Classic OPC, the aim of OPC UA was to eliminate the drawbacks of Classic OPC, especially its dependencies on Microsoft and COM/DCOM.

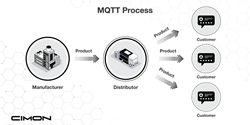

Four TCP-Based Communication Protocols That Are Key to IIoT-Part 1: MQTT

MQTT (Message Queuing Telemetry Transport) is a compact, binary, open, and easy-to-implement publish/subscribe messaging protocol. It is a certified OASIS and ISO standard (ISO/IEC 20922:2016) managed by the OASIS Technical Committee.

The Evolution of MQTT: Empowering Industrial Automation for 25 Years and Beyond

In manufacturing and industrial automation, the evolution of communication protocols has been pivotal in shaping operational efficiency, predictive maintenance, and overall innovation. Among these, MQTT stands as a beacon of connectivity

The Role of MQTT in Industrial Automation: Enhancing Connectivity and Efficiency

The Message Queueing Telemetry Transport protocol (MQTT), utilizes a client-server publish-subscribe architecture for data exchange. MQTT is useful in machine-to-machine and Industrial Internet of Things (IIoT) environments where bandwidth is typically limited.

Glass Manufacturer Modernizes Plants to Extract Value from OT Data from Edge to Cloud

They aimed to adopt a "hub and spoke" architecture to collect OT data, analyze it locally to make improvements, and share it with centralized enterprise and cloud systems for advanced analytics, machine learning, and AI across the business.

Records 1 to 8 of 8

Featured Product

Improve productivity and achieve consistent, high-quality welds with mechanized welding solutions.

We have the right welding system for every application. Our solutions are the ultimate in precision and efficiency, meeting the full scope of requirements for quality and reliability in tank, vessel, and pipeline construction in particular. We also offer custom solutions that stand up to any challenge. Working with our mechanized circumferential welding systems, you can weld components of very different sizes and weight classes-thanks to systems ranging from compact welding cells for smaller components through to robust systems for heavy workpieces. Cutting-edge technology and premium materials deliver top results, making our welding systems incredibly versatile, simple to use, and easy to maintain. Even welds, high process stability, and less rework are just a few of the advantages-and you can benefit too.

Manufacturing and Automation - Featured Company

Datanomix

Datanomix empowers manufacturers of all sizes to increase productivity and profitability through its Data-Powered Production™ solutions. Its product portfolio includes Production Monitoring, G-Code Cloud™ + DNC, TMAC AI™, and ToolAnalytix™ - all designed to turn machine data into actionable insights with zero operator input. Headquartered in New Hampshire, Datanomix software analyzes real-time production signals to identify bottlenecks, improve quality, and provide prescriptive coaching to drive continuous improvement. For more information, visit www.datanomix.io.