Beyond the Camera: Network Choices that Impact Machine Vision Systems

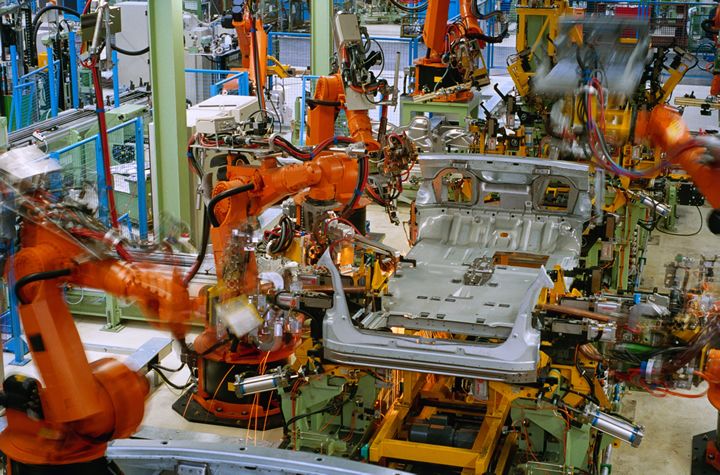

As automation accelerates, understanding the network that connects hardware with software will help ensure that machine vision systems operate at their full potential.

Prioritizing Network Investment in Manufacturing

Industry 4.0 is driving major gains in efficiency, automation, and innovation. But there's a flip side: That progress depends on fast, secure, always-on connectivity. Manufacturing, in particular, is an interesting case study.

BOOSTING OIL PAD OUTPUT WITH COMPREHENSIVE PIPE CORROSION MONITORING

Corrosion and erosion gradually reduce pipe wall thickness, increasing the risk of leaks or catastrophic failures-jeopardizing personnel safety, environmental protection, and asset integrity.

Benefits and Applications of IO-Link Wireless in the Food Industry

With IO-Link Wireless, food manufacturers and distributors can optimize their processes and stay ahead of the competition. The CoreTigo team provides a comprehensive look at how this works in a real factory setting.

Penn Waste Inc. Minimizes Machine Downtime and Improves Efficiency

Penn Waste realized that it needed an advanced wireless solution combined with smart sensors that would deliver accurate, reliable and continuous real-time data for predictive maintenance.

Shaping the Future-Proof Warehouse through Smart Connectivity

Future-proofing warehouse operations will require smart connectivity and specifically scalable, fluid network capacity and a new way of thinking about the invisible network that keeps the robots rolling in the warehouse of tomorrow.

Combining the Best of Both Worlds: Laying the Hybrid Network Foundation for a Smart Factory

Harnessing the full potential of these next-generation solutions demands a robust communication network capable of transporting vast amounts of data from the factory floor to the data center's IT infrastructure.

What is "Platform as a Service" and How Does it Improve Efficiencies in IIoT Ecosystems?

With each new IIoT device brought to market, manufacturers spent untold amounts of time and money making it live up to its potential. Time and again, they were building and rebuilding the same technology to enable data-based decision making, miles away from the device itself

Breaking down Walls to Build e-Factories

Thomas Burke, Global Strategic Advisor at CC-Link Partner Association (CLPA), looks at how industrial automation vendors, machine builders, and end users can futureproof robotic systems with value-adding network technologies.

Why smart interconnection is essential for building the factories of the future

Today, the super-high bandwidth and low latency of 5G have tremendous potential to transform all industries, especially manufacturing. They need intelligent networks to ensure manufacturers get the most from their 5G campuses.

Serving IoT Needs with Cassia Networks and Soracom

One factor that can complicate an IoT application is the crowding that may occur when many connected devices occupy the same area. To help corral all of these signals, many organizations opt to deploy Bluetooth gateways to help connect their IoT devices to the cloud.

Increasing Rural Broadband Can Help Rural Manufacturers Compete

Rural manufacturing's comparative decline is multifaceted, but the solution may not be. One of the most impactful distinctions between today's most and least competitive manufacturers is access to reliable, high-speed internet.

Interwire 2021 Trade Exposition - Industry 4.0 in Wire Manufacturing

Industry 4.0 is truly the future of manufacturing. Automation, robotics, machine learning, and data analytics are just a few examples of how the fourth industrial revolution affects the way wire and cable is made and how well companies compete on the world stage.

Benefits of VFD Cables Over THHN

Cables with the proper shielding, i.e. foil plus braided shield or semi-conductive fleece with foil and a braid shield, prevent the VFD system from radiating electrical noise that can interfere with the surrounding networking, wireless communication, and industrial devices.

Increase Security and Control Costs During Network Upgrades

While COVID-19 may have many legacies, one of them will definitely be an explosion in the amount of network capacity required. Most enterprises are experiencing the need for increased network capacity.

Records 1 to 15 of 23

Featured Product

Cold air to -50°F (-46°C) from your compressed air supply - with no moving parts!

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts.

Vortex tubes can produce:

"¢ Temperatures from -50° to +260°F (-46° to +127°C)

"¢ Flow rates from 1 to 150 SCFM (28 to 4248 SLPM)

"¢ Refrigeration up to 10,200 Btu/hr. (2571 Kcal/hr.)

Temperatures, flows and refrigeration are adjustable over a wide range using the control valve on the hot end exhaust.

EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation. https://exair.co/184_530

Manufacturing and Automation - Featured Company

KEB America, Inc.

KEB America is a trusted manufacturer of industrial automation products in North America. We manufacture, assemble, and support our German-engineered suite of controls, drives, motors, brakes, and clutches at an ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.