Two Industry Leaders - One Goal: Maximum Process Reliability

With software solutions from CSP, companies from a wide range of industries are taking their production processes to a whole new level. The result: greater efficiency, transparent quality assurance, and a decisive advantage on the path to the smart factory.

Hatz Engines - Case Study from CSP US Inc.

Before the introduction of CSP software, there was no integrated control of workflows, and the potential for process optimization remained untapped. Production relied on manual coordination, which led to efficiency losses and unnecessary error rates.

Mastering Manufacturing Excellence With a Quality Management System

Let's discuss what a QMS is, explore its core components and objectives, examine key industry standards like ISO 9001, AS9102, and ISO 13485, guide you through the implementation process and demonstrate how digital tools can enhance your QMS effectiveness.

Benefits and Applications of IO-Link Wireless in the Food Industry

With IO-Link Wireless, food manufacturers and distributors can optimize their processes and stay ahead of the competition. The CoreTigo team provides a comprehensive look at how this works in a real factory setting.

How to Ensure Your Corrective Actions Work, and Keep Working

Implementing corrective actions that are truly sustainable is a constant challenge. There always seem to be variables you didn't anticipate: A new person executing a process. An important piece of information unexpectedly unavailable. A gap in reporting.

Optimizing Your IT Ecosystem: Is It Time for a Tech Stack Audit?

A tech audit can serve as a diagnostic tool, flagging vulnerabilities within your packaging company's IT infrastructure before they impact the health of your business.

Driving Quality Control Excellence with MOM Integration

With MOM integration, compliance with regulatory standards becomes more manageable. Automated data collection and reporting streamline the process of preparing for audits and maintaining certification requirements.

ISO 9001: What's in it for you?

The decision to implement ISO 9001 is a business decision; and like all business decisions, you have to weigh the costs against the benefits. Also, you can implement ISO 9001 internally and stop there, or you can push ahead to seek certification.

Error-Proofing: The Key to Modern Manufacturing Success

For manufacturing engineers, a large part of the job is managing and eliminating risks. This process is called error-proofing, or poka-yoke in the industry.

In-Line Seal Strength Testing Using Thermal Cameras

In the realm of manufacturing precision, the assurance of product packaging integrity takes center stage. Using thermal cameras for in-line seal strength testing has revolutionized quality control and efficiency in the packaging industry.

Why Automated Optical Inspection Is a Winner in PCB Quality Control

Excelling in PCB quality control is a meaningful way to maintain competitiveness despite these conditions. Many decision-makers have increasingly invested in automated optical inspection (AOI) at their facilities. This approach leads to numerous benefits.

Why the Conventional Deep Learning Model is Broken

The conventional deep learning model is a supervised model. It takes months of time to develop and train the model before it is ready for the production line. Here, Karina Odinaev explains why the conventional deep learning model is broken and what the alternatives are.

Why training with few good images is fake news

As recently as five years ago, the only way to teach a machine vision system what a good product looked like was to laboriously show it every possible fault, mark and annotate the errors and catalogue them.

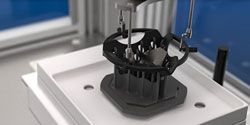

Unleashing the Potential: Quality Validation in Additive Manufacturing

As the adoption of AM grows across sectors ranging from aerospace to medical devices, one critical challenge remains: ensuring the quality and reliability of 3D printed components.

Why Visual AI Inspection Is Essential for Detecting PCB Defects

Artificial intelligence (AI) can help manufacturers handle quality control while managing larger volumes. Here are some compelling reasons people use visual inspection AI tools in modern production facilities.

Records 1 to 15 of 16

Featured Product

MOTION CONTROLLERS FOR MINIATURE DRIVES AND MICRODRIVES

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new Motion Controller is ideal for integration in equipment manufacturing and medical technology applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to approx. 100 W and is suitable for DC-motors with encoder, brushless drives or linear motors.

Manufacturing and Automation - Featured Company

NORD DRIVESYSTEMS

With four production facilities in the Midwest, on both coasts, and in the South, NORD is prepared to serve you with some of the shortest lead times in the industry. We house extensive component inventory, allowing us to assemble and ship 25% of all standard product orders same or next day!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)